Booster Oil is een internationaal smeeroliemerk. Er wordt gewerkt met een constante hoge kwaliteit basisolie en een uitgebalanceerd additievenpakket.

Om aan strenge eisen te voldoen, heeft Booster Oil de ideale producten geformuleerd die OEM’s van ons verwachten.

Booster Oil is een ‘Dutch inspired engineered product’ dat zijn oorsprong vindt in Nederland. Door de constant hoge kwaliteit basisolie met een uitgebalanceerd additieven pakket voldoen de producten van Booster aan alle strenge eisen en normen die auto- en machinefabrikanten aan smeermiddelen stellen.

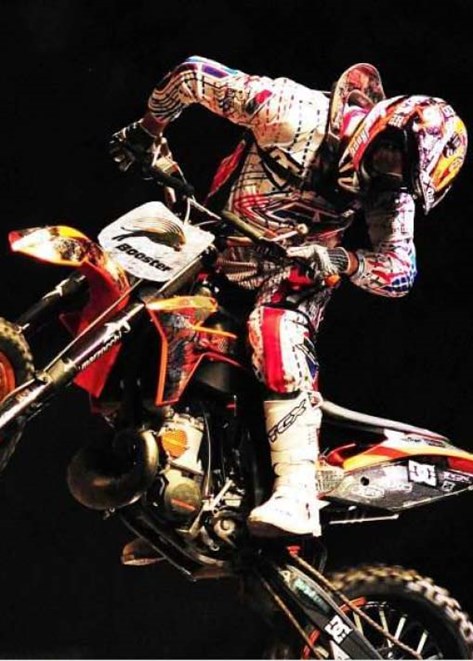

Door de zeer uitgebreide high performance producten laat Booster motoren en machines optimaal presteren. Om aan alle wensen van de gebruiker te voldoen worden de producten van Booster geleverd in een breed scala aan handelbare verpakkingen. Technische ondersteuning van specialisten en een extern laboratorium onderstrepen de kwaliteit van Booster. Sportiviteit en kwaliteit zijn het uitgangspunt.

Of je nu geconfronteerd wordt met nieuwe uitdagingen of u hebt een duidelijke visie, wij helpen je vooruit! Contacteer ons en wij nemen zo spoedig mogelijk contact met u op.

Maandag tot donderdag:

8:00 - 12:00 en 12:30 - 16:30

Vrijdag:

8:00 - 12:00 en 12:30 - 15:30

Zaterdag en zondag:

gesloten

Oudenaardestraat 49

8570 Vichte

Belgium